The principle

A dry separation toilet differs fundamentally from a water-flushed toilet in many ways. We would therefore like to explain the principle of the dry separation toilet on this page. There is also a standard on the subject of waterless sanitary systems, DIN 30762.

On this page we talk about how the toilet works, how to save water, how to ventilate and how to empty it.

How a dry separation toilet works

The separation in the toilet

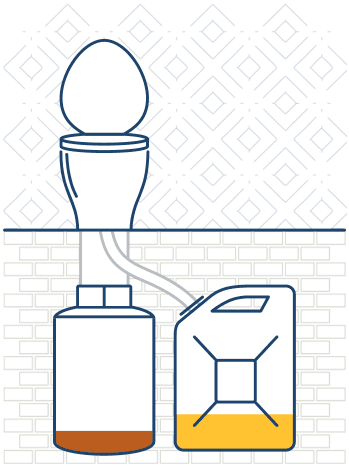

Urine and feces are substances that are clearly different from each other and our body already separates them. The dry separation toilet maintains this separation and is waterless.

The liquid urine is directed through hoses and pipes into collection containers, just as many men already know from waterless urinals.

Excrement fall by gravity into a collection tank. Both, the toilet seat and the down pipe, are designed in such a way that the feces are not visible or accessible. The collection containers are either barrels or our GOLDGRUBE®.

The containers are emptied with an appropriate vacuum pumping vehicle, since both material streams consist largely of water.

You can find out more about the toilet in general, our dry separation toilet and everything else you’ve always wanted to know about it in our interesting facts section or in our toilet blog.

The savings from a dry separation toilet

Urine contains large amounts of nutrients and feces consist of energy-rich, organic substances. If we do not mix urine and feces, or mix them with little water, then they remain valuable substances. Until the introduction of the water flush toilet, the materials were commonly used.

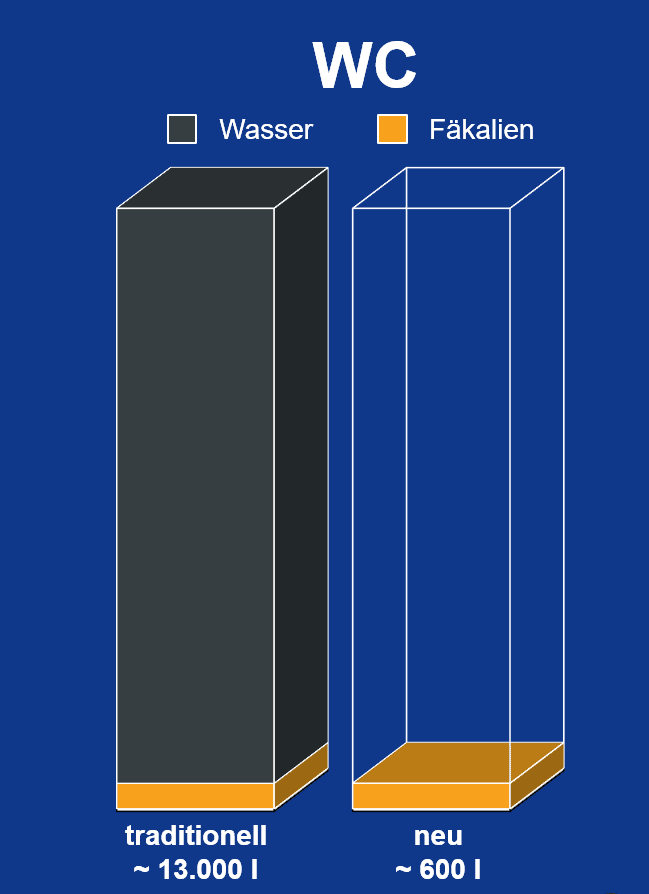

Traditional water toilets greatly dilute the amount of feces, turning 600 liters of excrement into 13,000 liters of dirty water. As a result, large amounts of wastewater must be transported and direct use is no longer possible. Subsequently, we as a society try to partially re-purify the wastewater in a wastewater treatment plant with a high input of energy and materials and then return the treated water to nature. However, it is not drinking water and still contains many pollutants. Some of the residual waste in the treatment plant is burned to produce energy, and the rest often ends up in garbage dumps.

In a waterless toilet, such as a dry separation toilet, no wastewater is produced and fecal matter does not enter the sewer system. As a result, the pollution of the remaining wastewater and the danger to the environment are significantly lower than with today’s dirty water. Thus, our modern toilets better protect the environment, as well as groundwater and human health.

The ventilation principle of our dry separation toilet

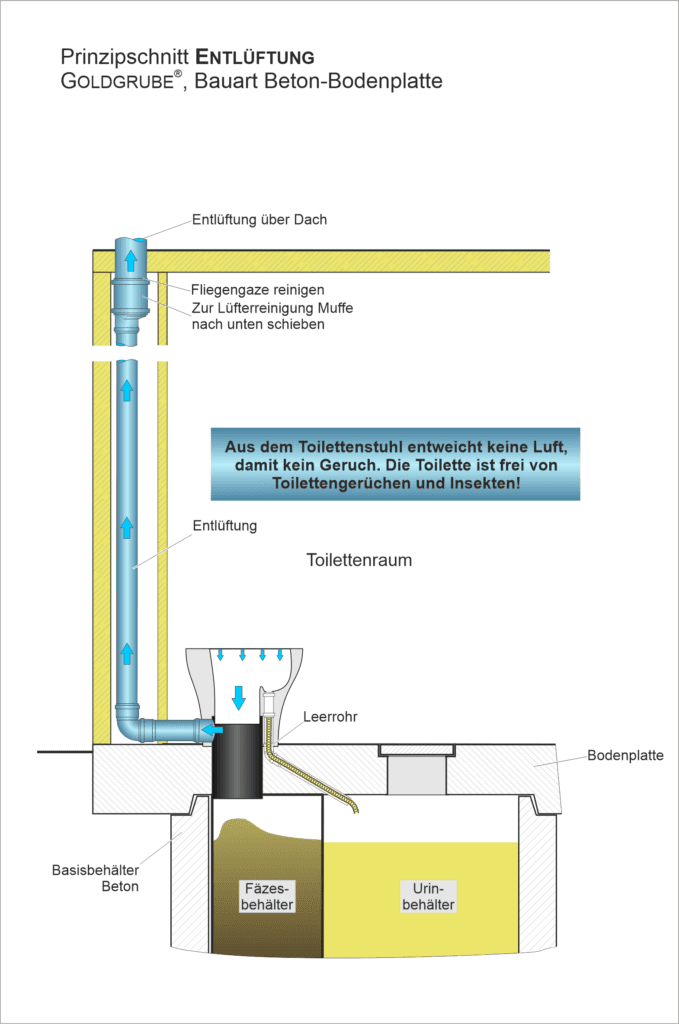

Our concept provides for separation of the two substances (feces and urine). These are stored separately in a vessel.

Due to the separation and continuous ventilation, no odors arise in the toilet room. On the one hand, this is much more hygienic, as the aerosols from the intestinal flora are not distributed in the room, and on the other hand, it also ensures that no insects are attracted.

The fan creates a draft of air into the toilet seat, which is then directed to the roof. This air draft thus creates a kind of air barrier to the feces tank.

Our ventilation concept in this case shows a TTC MINERAL and a GOLDGRUBE®. It is implemented in all versions, so also the TTC HOLZ as well as the barrel solution work with this principle.

Instructions for the installation of the venting can be found here.(German only)

The emptying process

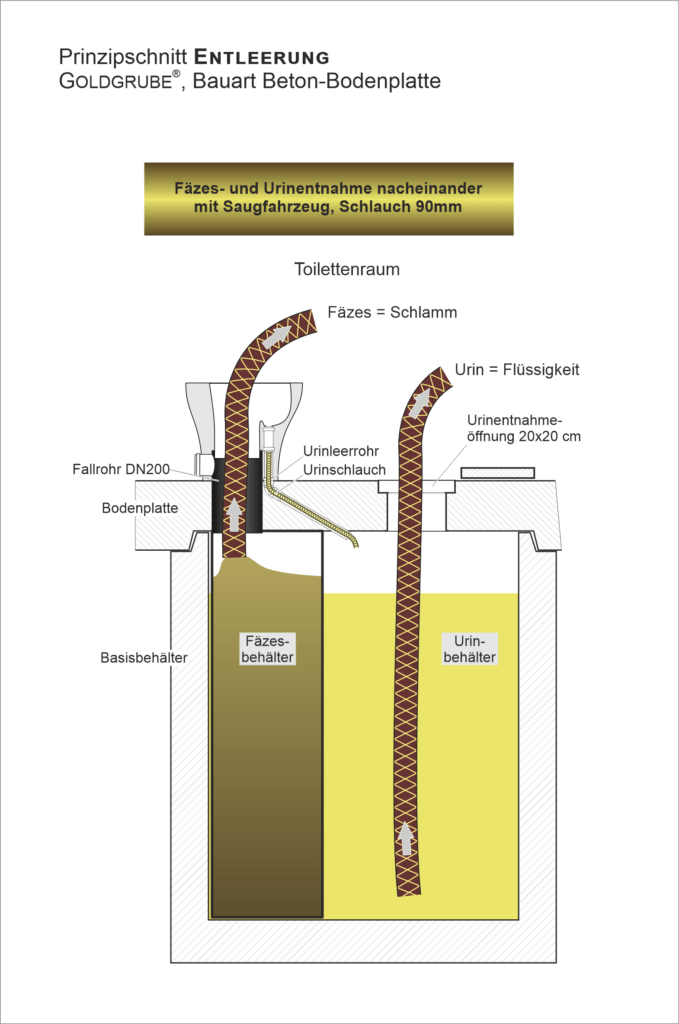

Emptying takes place via a discharge opening outside or inside the

inside the system, similar to a collection pit, but with significantly

significantly smaller quantities and therefore lower costs. In this example, emptying takes place inside the system.

Collection can be carried out by the wastewater association or a suitable

service provider using a standard suction vehicle.

We recommend that all customers empty their GOLDGRUBE® at least once a year. In the case of heavy or very heavy use, more emptying may be necessary.

The materials can then be disposed of separately or together in the local sewage treatment plant. The first companies and universities are looking at the option of processing the materials as resources. Energy generation, fertilizer or green hydrogen are just some of the areas being researched.